#multi turn electric actuator

Explore tagged Tumblr posts

Text

What is a multi turn electric actuator?

Multi turn electric actuators are sophisticated devices used to control the movement of valves and other mechanical systems that require rotation through multiple turns. Unlike their single-turn counterparts, which complete a full rotation in one turn, multi-turn actuators are designed to perform several revolutions, making them ideal for applications that involve more complex motion control. This article will explore the components, working principles, applications, advantages, and considerations associated with multi-turn electric actuators.

Components of Multi-Turn Electric Actuators

A typical multi-turn electric actuator consists of several key components:

Electric Motor: The core of the actuator, usually a DC or AC motor, converts electrical energy into mechanical energy. The choice of motor impacts the actuator's torque, speed, and efficiency.

Gearbox: Multi-turn actuators use gear mechanisms to multiply the torque generated by the motor while reducing the speed. The gearbox configuration determines the number of turns the actuator can make for each rotation of the motor.

Control System: This includes electronics that regulate the motor’s operation. It may involve simple on/off controls or advanced systems with feedback loops that adjust the actuator's position based on sensor input.

Output Shaft: This is the component that physically connects to the valve or mechanism being controlled. The output shaft rotates based on the actuator's motion.

Housing: The protective casing that encases the actuator's components, often designed to withstand environmental conditions such as moisture, dust, and temperature fluctuations.

Limit Switches: These are safety features that stop the actuator when it reaches its maximum or minimum position, preventing damage to the system.

Working Principle

The operation of a multi-turn electric actuator begins with the activation of the electric motor. The motor, controlled by an electrical signal, rotates the input shaft. This rotation is transmitted through a series of gears within the gearbox, which amplifies the torque and limits the speed. As the gears turn, they rotate the output shaft multiple times, allowing for precise positioning of the connected valve or device.

The control system plays a critical role in this process. Advanced multi-turn actuators can incorporate feedback mechanisms using position sensors. These sensors send real-time data about the shaft's position back to the control system, allowing for closed-loop control. This ensures that the actuator can make fine adjustments to reach the desired position accurately.

Applications

Multi-turn electric actuators are widely used in various industries due to their versatility and efficiency. Some common applications include:

Valves: They are often used in the oil and gas, water treatment, and chemical processing industries to control gate, globe, and butterfly valves.

Dampers: Multi-turn actuators can control dampers in HVAC systems, allowing for effective air flow regulation.

Robotics: In robotic systems, they provide precise movement for joints and grippers that require multiple turns for operation.

Industrial Automation: They are employed in conveyor systems, packaging machines, and other automated processes where precise control over movement is essential.

Hydraulic and Pneumatic Systems: Multi-turn actuators can control valves in hydraulic and pneumatic systems, ensuring optimal fluid or gas flow.

Advantages

The use of multi-turn electric actuators offers several benefits:

Precision: They provide high accuracy in positioning, crucial for applications where exact movements are necessary.

Energy Efficiency: Electric actuators are generally more energy-efficient compared to hydraulic or pneumatic systems.

Low Maintenance: With fewer moving parts and no need for hydraulic fluid, electric actuators typically require less maintenance.

Safety: Many models come with built-in safety features, such as limit switches, that prevent over-rotation and potential damage.

Versatility: They can be adapted for a wide range of applications, making them suitable for various industries.

Considerations

While multi-turn electric actuators have many advantages, there are some considerations to keep in mind:

Torque Requirements: It is essential to select an actuator that can provide sufficient torque for the application. Overloading can lead to failure.

Environmental Conditions: The actuator should be rated for the operating environment, including temperature extremes and exposure to corrosive substances.

Cost: Multi-turn actuators can be more expensive than simpler actuators, so budget considerations are crucial.

Complexity: The added complexity of these systems may require specialized knowledge for installation and maintenance.

Multi-turn electric actuators are vital components in modern automation and control systems. Their ability to provide precise, reliable movement across multiple turns makes them ideal for a wide array of applications, from industrial processes to robotics. By understanding their components, working principles, and advantages, users can make informed decisions when integrating these actuators into their systems.

0 notes

Text

The Benefits of Using Multi Turn Electric Actuators in Valve Control

In the ever-evolving world of industrial automation, the importance of reliable and efficient valve control cannot be overstated.

Valves are critical components in a wide range of industries, including oil and gas, water treatment, chemical processing, and power generation.

To ensure optimal performance and safety, these valves need precise control.

They offer a myriad of benefits that can significantly improve the efficiency and reliability of valve control systems.

In this article, we will explore the advantages of using multi turn electric actuators in valve control, with a focus on their role in industrial settings.

What are Multi Turn Electric Actuators?

Before diving into the benefits, it’s important to understand what multi turn electric actuators are.

These devices are a type of electric actuator specifically designed to operate valves that require multiple turns to open or close fully.

Multi-turn actuators convert electrical energy into mechanical torque, enabling them to precisely control the position of a valve.

They are commonly used with gate, globe, and other types of multi-turn valves, making them indispensable in various industrial applications.

Key Benefits of Multi Turn Electric Actuators in Valve Control

Precision and Accuracy

One of the primary benefits of using multi turn electric actuators is the high level of precision and accuracy they offer in valve control.

Unlike manual or pneumatic actuators, electric actuators can be programmed to achieve specific positions with exceptional accuracy.

This precision is crucial in applications where exact flow rates or pressures need to be maintained.

By providing consistent and repeatable valve positioning, multi turn electric actuators help ensure optimal process control and prevent costly errors.

Automation and Remote Operation

In today’s fast-paced industrial environment, automation is key to improving efficiency and reducing operational costs.

Multi turn electric actuators facilitate automation by enabling remote operation of valves.

This means that valves can be controlled from a central control room or even from off-site locations.

Remote operation not only enhances convenience but also improves safety by allowing operators to control valves in hazardous or hard-to-reach areas without having to be physically present.

Energy Efficiency

Multi turn electric actuators are known for their energy efficiency. Unlike pneumatic actuators that rely on compressed air systems, electric actuators use electricity directly, which can be more efficient and cost-effective.

Additionally, electric actuators consume power only when they are operating, as opposed to pneumatic systems that may continuously consume air.

This reduced energy consumption can lead to significant cost savings over time, especially in large-scale industrial operations.

Enhanced Safety

Safety is a top priority in industrial settings, and multi turn electric actuators contribute to safer operations.

Their precise control minimizes the risk of over-pressurization or leakage, which can lead to accidents or equipment damage.

Moreover, the ability to automate and remotely operate valves reduces the need for manual intervention, thereby decreasing the exposure of workers to potentially hazardous environments.

Reliability and Durability

Multi turn electric actuators are designed for reliability and long-term durability.

They are built to withstand harsh industrial conditions, including extreme temperatures, corrosive environments, and high vibration levels.

This robustness ensures that they provide consistent performance over extended periods, reducing the need for frequent maintenance and minimizing downtime.

Reliable valve control is essential for maintaining continuous operations and preventing disruptions in critical processes.

Flexibility and Adaptability

Another advantage of multi turn electric actuator is their flexibility and adaptability.

They can be easily integrated into existing control systems and customized to meet specific application requirements.

Whether it’s adjusting torque settings, programming specific valve positions, or integrating with advanced control systems, multi turn electric actuators offer a high degree of adaptability.

This makes them suitable for a wide range of applications, from simple on/off control to complex modulating operations.

Environmental Friendliness

In an era where environmental concerns are increasingly important, multi turn electric actuators offer a greener alternative to pneumatic actuators.

By eliminating the need for compressed air systems, they reduce the overall energy consumption of industrial facilities.

Additionally, electric actuators do not produce emissions, making them an environmentally friendly choice for companies looking to reduce their carbon footprint.

Conclusion

The use of multi turn electric actuators in valve control offers numerous benefits, including precision, automation, energy efficiency, safety, reliability, flexibility, and environmental friendliness.

These advantages make them an ideal choice for industries that rely on accurate and efficient valve control. As technology continues to advance, the role of multi turn electric actuators in enhancing industrial automation will only become more significant.

For businesses in Ahmedabad looking to improve their valve control systems, consider partnering with industry experts.

Cair Euromatic offers cutting-edge multi turn electric actuators designed to meet the demands of modern industrial applications, ensuring superior performance and reliability.

By investing in multi turn electric actuators, companies can not only enhance their operational efficiency but also contribute to a safer and more sustainable future.

0 notes

Text

Extract from Thirkenforth Locomotive Works' 1937 Product Catalogue

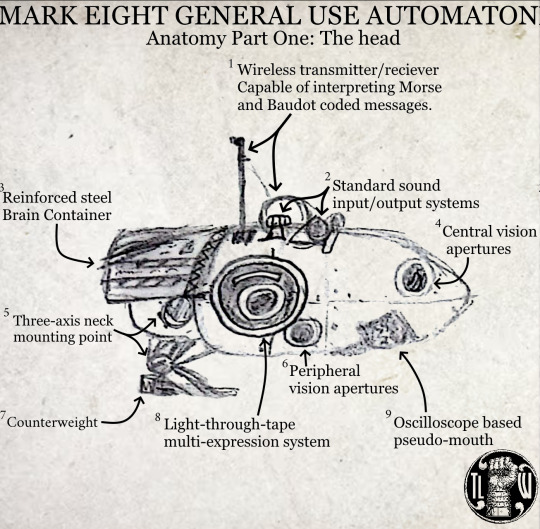

MARK EIGHT GENERAL USE AUTOMATON Anatomy, Part One: The Head 1. Wireles transmitter/reciever, capable of interpreting Morse and Baudot coded messages.

2. Standard sound input/output systems (A simple microphone and pair of speaker cones)

3. Reinforced steel Brain Container (General Use Automatons, or GUAs use a used human brain to manage logical decisions of all kinds)

4. Central Vision Apertures

5. Three-axis neck mounting point (Allows the head to turn in all directions)

6. Peripheral vision apertures

7. Counterweight (The head of a GUA is heavy, and thus needs to be balanced out on the other side)

8. Light-through-tape multi-expression system -a pseudo-eye

9. Oscilloscope-based pseudo-mouth (As GUAs are run by a human brain, they still retain the capability to feel emotions, though typically less so than the average person. The pseudo-eyes and mouth are systems by which a GUA may have a level of emotional expression.)

MARK EIGHT GENERAL USE AUTOMATON Anatomy, Part Two: The Arms

Two-Axis articulated digits -the fingers can bend in two directions, offering it a wider range of ways to grip things

Hydraulically actuated elbow joints give a high torque for lifting heavy objects.

Thirkenforth standard palm electromagnet for handling metallic objects -This is particularly useful for objects with no easy surface to grab onto.

Wide range of thumb motion allows for a stronger grip.

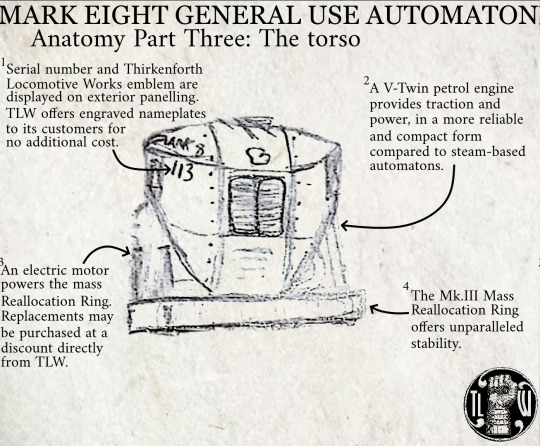

MARK EIGHT GENERAL USE AUTOMATON Anatomy, Part Three: The torso 1. Serial number and Thirkenforth Locomotive Works emblem are displayed on exterior panelling. TLW offers engraved nameplates to its customers for no additional cost.

2. A V-Twin petrol engine provides traction and power, in a more reliable and compact form compared to steam-based automatons.

3. An electric motor powers the Mass Reallocation Ring. Replacements may be purchased at a discount directly from TLW in the case of failure.

4. The Mk.III Mass Reallocation Ring offers unparalleled stability. The Mark Eight GUA actually uses two stacked on top of each other, such that the force created by movement of internal weights in one ring can be counteracted by the other.

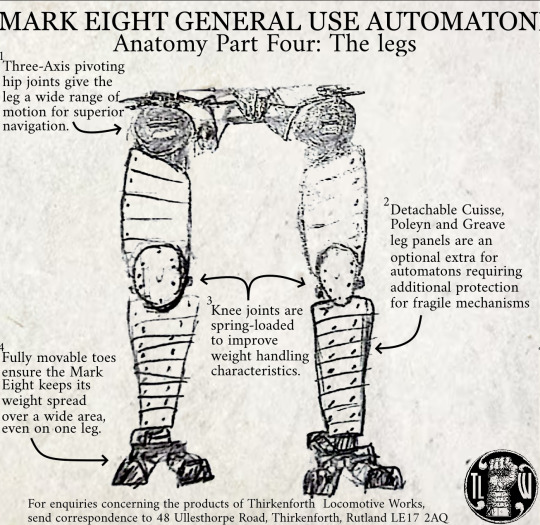

MARK EIGHT GENERAL USE AUTOMATON Anatomy Part Four: The legs

Three-Axis pivoting hip joints give the leg a wide range of motion for superior navigation.

Detachable 'Cuisse', 'Polyen' and 'Greave' leg panels are an optional extra for automatons requiring additional protection for fragile mechanisms.

Knee joints are spring-loaded to improve weight handling characteristics.

Fully movable toes ensure the Mark Eight keeps its weight spread over a wide area, even on one leg.

For enquiries concerning the products of Thirkenforth Locomotive Works, send correspondence to 48 Ullesthorpe Road, Thirkenforth, Rutland LE17 2AQ.

3 notes

·

View notes

Text

Guide to choosing the right ball valve for your project

Parth Valves and Hoses LLP, a trusted provider of high-quality hygienic valves, FDA hoses, and dampers, understands the critical role fluid control plays in various industries. Selecting the right valve is essential for ensuring efficient, safe, and reliable operations. This comprehensive guide focuses on ball valves, providing in-depth insights into their functionality, types, applications, and key considerations for choosing the perfect valve for your specific project.

What is a Ball Valve?

A ball valve is a quarter-turn rotational valve that utilizes a hollow, spherical ball to control the flow of liquids or gases. The ball has a bore (a hole through its center) that allows or blocks flow depending on its position. When the bore is aligned with the flow direction, the valve is open, allowing unimpeded flow. A simple 90-degree rotation of the ball, typically using a lever or handle, positions the solid part of the ball to block the flow path, effectively closing the valve and creating a tight seal.

Ball Valves

Advantages of Ball Valves:

Ball valves offer several advantages that make them a popular choice in various industrial applications:

Quick and Easy Operation: The quarter-turn operation enables rapid opening and closing, making them ideal for emergency shut-off situations and processes requiring frequent on/off control.

Excellent Shut-Off Capability: When closed, ball valves provide a reliable and leak-tight seal, preventing leakage and ensuring efficient flow isolation.

Durability and Reliability: With relatively few moving parts, ball valves are known for their robust construction, minimal maintenance requirements, and long service life.

Versatility: Ball valves can handle a wide range of fluids and gases, including corrosive chemicals, making them suitable for diverse industrial applications.

Compact Design: Their compact design makes them suitable for installations with limited space.

Cost-Effectiveness: Compared to some other valve types like gate or globe valves, ball valves often offer a more cost-effective solution for many applications.

Types of Ball Valves:

Different types of ball valves are available to suit various applications:

One-Piece Ball Valves: These are the most economical type, typically used for low-pressure applications.

Two-Piece Ball Valves: Offer greater versatility and can be easily disassembled for cleaning or maintenance.

Three-Piece Ball Valves: Provide easy access to internal components for maintenance and repair, making them suitable for demanding applications.

Multi-Port Ball Valves: These valves have three or more ports, allowing for complex flow control and diversion.

Key Considerations When Choosing a Ball Valve:

Selecting the appropriate ball valve is crucial for optimal performance, safety, and longevity. Consider the following factors:

Material Compatibility: The valve body, ball, and seals must be chemically compatible with the media being handled. Common materials include:

Stainless Steel: Offers excellent corrosion resistance and is suitable for food processing, chemical, and pharmaceutical applications.

Brass: Cost-effective for water and other non-corrosive media.

PVC: Suitable for corrosive applications at lower temperatures and pressures.

Pressure and Temperature Ratings: The ball valve must be rated to handle the maximum operating pressure and temperature of the system.

Port Configuration: Choose the appropriate port configuration (2-way, 3-way, etc.) based on the specific flow control requirements of your system.

Valve Size: Proper sizing is crucial to ensure optimal flow rates and minimize pressure drop.

End Connections: Select end connections (threaded, flanged, welded) compatible with the piping system.

Actuation: Consider the actuation method based on control needs: manual, electric, or pneumatic.

Seat and Seal Materials: The seat and seal materials (e.g., PTFE, Viton) must be compatible with the media and operating temperature.

Parth Valves and Hoses LLP: Expertise in Fluid Control

While Parth Valves and Hoses LLP specializes in hygienic valves, FDA hoses, and dampers, our deep understanding of fluid control principles allows us to provide expert guidance on selecting the right ball valve for various applications. We can assist you in determining the appropriate material, size, and configuration for your specific needs.

Why Choose Parth Valves and Hoses LLP for Your Fluid Control Needs?

Expert Knowledge: Our team possesses extensive knowledge of fluid control systems and components.

Commitment to Quality: Our 12-month product guarantee on our hygienic products reflects our dedication to quality and reliability.

Customer-Centric Approach: We prioritize customer satisfaction and provide excellent support.

Conclusion:

Selecting the correct ball valve is a critical decision that impacts the efficiency and safety of your operations. By carefully considering the factors outlined in this guide and consulting with fluid control experts like those at Parth Valves and Hoses LLP, you can ensure you choose the ideal valve for your project. Contact us today to discuss your specific requirements and discover how we can contribute to your success.

0 notes

Text

Safety Design of Household Anti-Electric Shock Metal Pushbutton Switches

Introduction

In household electronic devices, safety is a paramount concern, especially when it comes to protecting children from accidental electric shock or unintended activation. Metal pushbutton switches are widely used in various appliances due to their durability and reliability, yet traditional designs may expose children to potential safety risks. This article explores the technology and design principles behind child-safe, anti-electric shock metal pushbutton switches. Topics include incorporating insulation layers within the switch design to enhance safety and examples of metal pushbutton switches in household electrical systems.

1. Anti-Electric Shock Technology in Metal Pushbutton Switches

The design of anti-electric shock metal pushbutton switches must focus on shielding the user from contact with live parts, ensuring that even accidental or forceful interaction remains safe. Here are some essential technologies and design considerations for enhancing switch safety:

1.1 Child-Proof Activation Mechanism

To prevent children from accidentally activating household appliances, switches can be designed with child-resistant features. These designs can incorporate multi-step activation processes or additional barriers that require an adult’s strength or dexterity:

Two-Step Activation: Adding a two-step process, such as pushing and then turning or pressing two adjacent buttons simultaneously, reduces the likelihood of accidental activation by young children.

Increased Actuation Force: By increasing the pressure required to activate the switch, designers can make the button harder for young children to press while still manageable for adults.

1.2 Insulated Touch Protection

Ensuring that the user cannot come into contact with any conductive or live parts inside the switch is critical. Metal pushbutton switches in home appliances can integrate the following designs for added protection:

Insulating Layers: Applying a non-conductive insulating layer between the switch cover and the internal conductive components is highly effective in preventing electric shock. For example, insulating materials such as polycarbonate or ABS can be used on the outer casing to create a safe barrier.

Double Insulation Structures: A double-layer insulation design, with one layer protecting the internal switch mechanics and another preventing contact through the metal casing, further minimizes shock risk.

1.3 Enhanced Waterproof and Dustproof Protection

In household environments, metal pushbutton switches are often exposed to moisture and dust, which can potentially lead to short circuits or corrosion. High IP-rated switches provide effective insulation from these elements and ensure long-term safety:

IP68-Rated Switches: Using waterproof seals, such as silicone gaskets around the button edges, enhances the switch’s protection against dust and water ingress. This feature is particularly valuable in kitchen appliances and bathroom devices.

Moisture-Resistant Insulation: Coating or encapsulating the switch components with moisture-resistant materials protects the internal circuit and ensures that the switch remains functional and safe in humid environments.

2. Integrating Anti-Electric Shock Insulation Layers in Switch Design

For enhanced household safety, metal pushbutton switches can be designed with built-in insulation to prevent accidental electric shock. This section details methods of integrating protective layers within the switch:

2.1 Internal Insulation Layer

An internal insulation layer made of high dielectric strength materials, such as polyimide or polyester, can be installed within the switch housing. This layer acts as a protective barrier, preventing accidental contact with conductive parts even if the outer layer is damaged.

2.2 Protective Casing with Shock Resistance

Using non-conductive casings made of impact-resistant materials like ABS or polycarbonate protects the switch’s internal components. This layer not only insulates the switch but also enhances its durability, reducing the risk of wear and tear that could expose live parts.

2.3 Enclosed Actuator Design

In a fully enclosed actuator design, all moving parts are housed within a non-conductive shell, which prevents direct contact with the actuator mechanism. This design can be beneficial for household devices where frequent interaction with the switch is expected, as it further minimizes the risk of accidental electric shock.

3. Application Examples of High-Safety Metal Pushbutton Switches in Household Electrical Systems

High-safety metal pushbutton switches have various applications in household control systems, where enhanced safety measures are particularly beneficial.

3.1 Smart Home Control Panels

In smart home systems, control panels equipped with child-safe, anti-shock metal pushbutton switches ensure safe operation for all family members. For example, switches with child-resistant actuation mechanisms provide peace of mind in family rooms or children’s play areas.

3.2 Kitchen and Bathroom Appliances

Household appliances in kitchens and bathrooms are frequently exposed to moisture, which increases the risk of electric shock. Metal pushbutton switches with IP68-rated designs and insulating layers are essential for these environments, where high safety standards are crucial. Examples include waterproof kitchen appliance controls, bathroom lighting switches, and shower heater control panels, which benefit from anti-shock designs.

3.3 Electrical Safety Control for Lighting and HVAC Systems

For lighting and HVAC controls in households, anti-electric shock metal pushbutton switches provide reliable safety features. Using shock-resistant materials and insulation layers, these switches ensure safe operation while maintaining high durability in high-use areas like living rooms and hallways.

Conclusion

The development of anti-electric shock metal pushbutton switches for household appliances highlights the need for reliable and child-safe designs. By incorporating child-resistant mechanisms, insulating layers, and moisture-resistant materials, manufacturers can deliver products that prioritize household safety. The application of high-safety metal pushbutton switches in kitchens, bathrooms, and smart home control panels demonstrates the value of safety-focused design in modern household systems.

en.dghongju.com

0 notes

Text

Actuator Dampers, Fabricated Valves, Electrical Dampers

Actuator Dampers, Fabricated Valves, Electrically Operated, Pneumatically Operated Damper, Industrial Butterfly Dampers, Multi Louver, Manufacturer, India.

Actuator, Actuators, Electrical Actuator, Electrical Actuators, Emtork Actuator, Emtork Actuators, Regeltek Actuator, Regeltek Actuators, Quarter Turn Actuator, Quarter Turn Actuators, Electrical Thruster, Electrical Thrusters, Motorised Valve, Motorised Valves, Damper, Dampers, Flame Proof Unit, Flame Proof Units, Explosion Proof Unit, Explosion Proof Units, Spur Gearbox, Spur Gearboxes, Single Flap Butterfly Damper, Single Flap Butterfly Dampers, Electrically Operated Damper, Electrically Operated Dampers, Automated Valve, Automated Valves, Automated Damper, Automated Dampers, Multi Louver Damper, Multi Louver Dampers, Guillotine Damper, Guillotine Dampers, High Temperature Damper, High Temperature Dampers, High Performance Damper, High Performance Dampers, Electrically Operated Butterfly Valve, Electrically Operated Butterfly Valves, Pneumatically Operated Butterfly Valve, Pneumatically Operated Butterfly Valves, Ball Valve, Ball Valves, Slide Gate, Slide Gates, Electrically Operated Globe Valve, Electrically Operated Globe Valves, Gate Valve, Gate Valves, Electrically Operated Guillotine Damper, Electrically Operated Guillotine Dampers, Air Diverter, Air Diverters, Material Diverter, Material Diverters, Poppet Damper, Poppet Dampers, Manufacturer Supplier Exporter, Pune Maharashtra India.

0 notes

Text

0 notes

Text

We are a Manufacturer, Supplier, and Exporter of Motorized Valves (Motorised Valves) and Valve actuators based in Chennai, Tamil Nadu, India.

Sensoware Offers Various types and sizes of Valves, such as Butterfly, Ball, Sluice, Globe, and dampers with Electrical Actuators. Our Valves and Electric Actuators are available in Quarter Turn and Multi-Turn type with ON/OFF or Modulating Functions.

0 notes

Text

Top Industrial Component Suppliers in Dubai: Alphatronic Machinery’s Comprehensive Range

Are you looking for high-quality industrial components in Dubai? Look no further than Alphatronic Machinery, your one-stop solution for a wide range of essential industrial fittings and valves. In this blog, we’ll explore some of the key products offered by this leading supplier, including food grade fittings, limit switches, Namur valves, ball valves with actuators, and automatic valves with electrical actuators.

Food Grade Fittings suppliers in Dubai: Ensuring Safety and Hygiene

When it comes to food and beverage processing, safety is paramount. Alphatronic Machinery offers a comprehensive selection of Food Grade Fittings suppliers in Dubai that meet strict industry standards. These fittings are designed to prevent contamination and ensure the highest levels of hygiene in your production processes. From sanitary clamps to tri-clamp fittings, Alphatronic Machinery has you covered.

Limit Switch suppliers in Dubai: Precision Control for Your Equipment

Precise control is essential in many industrial applications. Alphatronic Machinery supplies a variety of Limit Switch suppliers in Dubai that provide accurate position sensing and control. These switches are crucial for ensuring the safe and efficient operation of your machinery, offering reliable performance even in challenging environments.

Namur Valve Suppliers Dubai: Streamlining Pneumatic Systems

For those in need of standardized pneumatic valve solutions, Alphatronic Machinery offers a range of Namur Valve Suppliers Dubai. These valves are designed to interface seamlessly with actuators, making them ideal for use in process automation applications. Their standardized mounting pattern ensures easy installation and maintenance.

Ball Valve with Actuators Suppliers in Dubai: Efficient Flow Control

Alphatronic Machinery provides Ball Valve with Actuators Suppliers in Dubai, offering a complete solution for flow control in various industries. These valve-actuator combinations provide precise and reliable control, whether you need on-off functionality or modulating control. The actuators can be pneumatic, hydraulic, or electric, catering to different system requirements.

Automatic Valve with Electrical Actuator Suppliers in Dubai: Advanced Automation

For applications requiring advanced automation, Alphatronic Machinery supplies Automatic Valve with Electrical Actuator Suppliers in Dubai. These systems offer precise control and can be easily integrated into your existing control systems. Whether you need quarter-turn or multi-turn actuation, Alphatronic Machinery has options to suit your needs.

Why Choose Alphatronic Machinery?

As a trusted supplier in Dubai, Alphatronic Machinery offers: - High-quality products from reputable manufacturers - Expert technical support and advice - Competitive pricing - Quick delivery times - A wide range of industrial components under one roof

Whether you’re in the food and beverage industry, oil and gas, or any other industrial sector, Alphatronic Machinery has the components you need to keep your operations running smoothly and efficiently.

For more information on their product range or to request a quote, visit Alphatronic Machinery’s website or contact their sales team today. Experience the difference that quality industrial components can make in your operations with Alphatronic Machinery, your trusted supplier in Dubai.

0 notes

Text

Ball Valve Manufacturer in USA

SVR Global is the well-known Ball valve manufacturer in USA. A ball valve is a shut-off valve that rotates a ball with a bore inside it to permit, restrict, and control the flow of liquids, gases, and vapors in a pipe system. The shaft that connects the ball to the operational and controlling mechanism that rotates the ball is mounted against two seats. The fluid is not allowed to pass through the valve when the cross-section of the bore is perpendicular to the area of the flow. The area of the bore that is exposed to the floor determines how much fluid flows through the valve and at what pace. They can be turned manually, with the aid of an actuator, a wrench, or a lever that is manually turned by the operator. To open or close the valve, torque is exerted to move the lever arm by 90 degrees in either a clockwise or counterclockwise direction. The valve is open if the lever arm is perpendicular to the pipe. A closed valve is indicated by the lever arm being perpendicular to the pipe. To meet varied industrial applications, it is available in a variety of designs and characteristics. Depending on the industry in which this valve is used, different norms and specifications apply. Ball valve can be utilized for extremely corrosive or viscous fluids that harden at room temperature. These valves are manufactured in the USA.

Types:

Full port ball valve

Forged Ball Valve

Reduced port ball valve

Floating ball valve

Trunnion ball valve

Top entry ball valve

Multi-port ball valve

V-port ball valve

Three-way ball valve

Industries:

Ball valves are utilized in water treatment plants, wastewater treatment plants, and distribution systems for controlling the flow of water, chemicals, and sludge.

Natural Gas Industries

Manufacturing Sectors

Chemical Storage Industries

Oil & Gas Industries

Textile Industries

Mining Industries

Marine Industries

Applications:

Oil and gas

Chemical processing

Water and wastewater treatment

Power generation

Pulp and paper

Marine and offshore

Aerospace

Advantages:

These valves are made using a forging process that results in a stronger and more durable valve compared to those made using casting or machining methods.

These valves can be made from a range of materials that offer excellent corrosion resistance, including stainless steel, alloy steel, and other exotic alloys.

These valves provide precise flow control by rotating the ball to either block or allow flow through the valve.

These valves are easy to operate and require minimal maintenance, making them a popular choice in a wide range of applications.

Quick opening and closing of valves.

Description:

Body Material: Cast iron, WCB, WCC, WC6, LCC, LCB, Titanium, SS304, SS316, CF8, CF8M, F55, F51, F53, Monel, Ductile Iron.

Class: 150-2500, PN10 to PN450

Size: DN15 TO DN1200

Operations: Lever operated, electric actuated, pneumatic actuated, gear operated

Ends: threaded, socket-weld, flanged, buttweld

0 notes

Text

0 notes

Link

0 notes

Link

0 notes

Text

Non Lubricated Plug Valve Manufacturer in India

Specialityvalve is the leading Non Lubricated Plug Valve Manufacturer in India. Non Lubricated plug valves are robust in construction and easy to maintain inline. It has a sleeve or liner installed in the cavity. The narrow plug wedges the sleeve against the plug body. The non-metallic sleeved decreases friction during operation.

These valves are sleeved quarter-turn plugs that achieve sealing using a compressible sleeve as a sealing member. Nonlubricated plug valves are bi-directional flow, simple actuation, lightweight, compact design, and multiport configurations all of which improve the design system. It is limited by the temperature and chemical compatibility of non-metallic materials.

The Plug Valve is a quarter-turn rotary motion manual valve. It offers a straightway passage through the ports so that fluid can flow through the opening plug (cylindrical or tapered plug) with a minimum of turbulence. The plug Valve is different from other valves due to its plug disc design. An important feature of the plug valve is its ease to adapt to multiport construction and these ports are widely used. It gives benefits like simplified piping and installation, and the elimination of costly pipe fitting.

Specialityvalve is a well-known Non Lubricated Plug Valve Manufacture in India which provides its premium quality products which come in various materials and designs. All the products are tested according to the requirements of the clients.

Advantages of non lubricated plug valve

Available in multi-port design

Easy to install

Improve seal with injected sealant

leak-proof

Easy to open or close

Disadvantages of non lubricated plug valve

High friction is needed

It is costlier

Larger valves needed for actuators

Applications of non lubricated plug valve

Natural gas piping

Sewage applications

Coal slurries

Sewage applications

Parts of non lubricated plug valve

Handle

Gland

Body

Plug

Plug port

Stem

Body materials: CF8, CF8M, CF3, CF3M, Ductile iron, WCB, WCC, WC9, WC6, Alloy 20, SS304, SS316, CF8M, SS316L, SS904L

Size:1/2”-14”

Class: 150 to 2500, PN16 to PN63

End: Flanged, Socket weld, Butt weld, Screwed, threaded.

Operations: Electric Actuator, Pneumatic Actuator.

https://www.specialityvalve.com/product-category/non-lubricated-sleeved-plug-valve/

0 notes

Text

The types and benefits of using automation valve

A valve which works with no manual endeavours is an automation valve. Such valves can be actuated with the assistance of Pneumatics, hydraulics, electrically or with a mix of these.

Types of automation valves

Every one of the most widely recognized sorts of automation valves can be categorized as one of three primary classes. They are linear, rotary, and self-actuated. There is an assortment of valve types inside every one of these classes each having its advantages.

Rotary Valves

These sorts of valves depending on the rotating movement of the flow obstructer. Generally speaking, this rotation is restricted to 90 degrees or one quarter-turn, in any case, some valves work utilizing a bigger level of rotation and have more than 2 positions that are utilized in ordinary activity. Examples of quarter-turn valves are ball valves, plug valves, and butterfly valves.

Linear Valves

There are 2 particular kinds of straight valves: rising stem and axial. While both valve types depend on the linear movement of the flow obstructer, they are different in development and activity.

Multi-turn rising stem valves move the obstructer by the rotation of a threaded pole which is connected to the obstructer These valve types have the use for flow control applications.

Axial valves utilize pneumatic or electromagnetic force to slide the obstructer along an axis. These valves are commonly effective and utilized for on/off process applications.

Benefits of using automation valve

Automation assists with exercises and processes without the requirement for persons to truly take part in doing them. Automation valves are especially important for controlling flow in piping frameworks requiring accuracy control or fail-safe crisis shutoff.

The Effect of Automated Valve Actuators

The utilization of automation valve actuators influences a few parts of assembling and various types of handling, which could incorporate dangerous materials, oil and gas, chemicals, food and refreshment, and others. Operating valves physically represents a progression of dangers.

Automated valve actuators furnish administrators with a more effective, smoothed-out control of piping framework flows working with accurate expenses per unit.

Enhancing Output with Automated Valves

Further developed output control utilizing automated valves assists with reducing expenses connected with item waste. Automated valves don't rely upon an administrator, which permits them to proceed to adjust and change flow through a framework without interference.

Enhanced Safety with Automated Valve Actuators

Adding to administrator safety, actuator valves help to control predictable working levels and maintain security in conditions where outrageous temperatures, pressure levels, harmful vapours, combustible components, or different conditions can make disastrous failures. In crises, automated valve actuators return to fail-safe positions, forestalling mishaps, ecological perils, harm to hardware or designs, and other destroying results.

If you desire to have the best quality automation valve, contact Agile Valves Co., LTD at +0086 21 60343533 to place an order.

0 notes

Text

Pneumatic Actuators, Pneumatically Operated Valves, Exporter

Pneumatic Actuators, Pneumatically Operated Valves, Pneumatically Actuated Valves, Accessories, Double Acting Actuators, Butterfly Valves, Manufacturer.

Pneumatic Actuators, Pneumatically Operated Valves, Pneumatically Actuated Valves, Pneumatic Valves, Pneumatic Actuator Accessories, Double Acting Actuators, Pneumatic Actuated Butterfly Valves, Pneumatic Butterfly Valves, VT Series Pneumatic Actuator, Actuator, Actuators, Electrical Actuator, Electrical Actuators, Emtork Actuator, Emtork Actuators, Regeltek Actuator, Regeltek Actuators, Quarter Turn Actuator, Quarter Turn Actuators, Electrical Thruster, Electrical Thrusters, Motorised Valve, Motorised Valves, Damper, Dampers, Flame Proof Unit, Flame Proof Units, Explosion Proof Unit, Explosion Proof Units, Spur Gearbox, Spur Gearboxes, Single Flap Butterfly Damper, Single Flap Butterfly Dampers, Electrically Operated Damper, Electrically Operated Dampers, Automated Valve, Automated Valves, Automated Damper, Automated Dampers, Multi Louver Damper, Multi Louver Dampers, Guillotine Damper, Guillotine Dampers, High Temperature Damper, High Temperature Dampers, High Performance Damper, High Performance Dampers, Electrically Operated Butterfly Valve, Electrically Operated Butterfly Valves, Pneumatically Operated Butterfly Valve, Pneumatically Operated Butterfly Valves, Ball Valve, Ball Valves, Slide Gate, Slide Gates, Electrically Operated Globe Valve, Electrically Operated Globe Valves, Gate Valve, Gate Valves, Electrically Operated Guillotine Damper, Electrically Operated Guillotine Dampers, Air Diverter, Air Diverters, Material Diverter, Material Diverters, Poppet Damper, Poppet Dampers, Manufacturer Supplier Exporter, Pune Maharashtra India.

0 notes